Glass Molded Aspherical Lenses

| Item Code | Material | OD(mm) | EFL(mm) | WD(mm) | CT(mm) | NA | Design Wavelength (mm) | Laser Window (mm) |

|---|---|---|---|---|---|---|---|---|

| AL01140240 | D-ZLAF52LA | 2.40 | 1.14 | 1.129/4.826 | 1.239 | 0.43/0.124 | 1300 | BK7, t=0.30 |

| AL01140241 | D-ZLaF52LA | 2.40 | 1.14 | 0.720 | 1.24 | 0.55 | 1310 | N/A |

| AL01400240 | D-ZK3 | 2.40 | 1.45 | 0.88 | 1.00 | 0.560 | 780 | N/A |

| AL02000300 | D-ZK3 | 3.00 | 2.00 | 1.09 | 2.00 | 0.50 | 780 | BK7, t=0.25 |

| AL02750450 | D-ZLaF52LA | 4.50 | 2.75 | 1.50 | 2.24 | 0.64 | 830 | N/A |

| AL03100630 | D-ZK3 | 6.325 | 3.10 | 1.76 | 3.214 | 0.670 | 830 | N/A |

| AL03200300 | D-ZLaF52LA | 3.00 | 3.20 | 2.09 | 2.00 | 0.37 | 633 | N/A |

| AL03760300 | D-ZK3 | 3.00 | 3.76 | 2.98 | 1.50 | 0.33 | 635 | BK7, t=0.25 |

| AL04000400 | D-ZK3 | 4.00 | 4.00 | 2.91 | 2.00 | 0.40 | 405 | BK7, t=0.25 |

| AL04050630 | D-ZK3 | 6.33 | 4.05 | 2.80 | 3.10 | 0.63 | 445 | PC, t=1.20 |

| AL04020631 | D-LAK6 | 6.325 | 4.02 | 2.41 | 2.90 | 0.60 | 408 | BK7, t=0.25 |

| AL04470540 | D-ZK3 | 5.42 | 4.47 | 3.08 | 3.45 | 0.47 | 780 | PC, t=1.20 |

| AL04500300 | D-ZK3 | 3.00 | 4.50 | 3.46 | 1.78 | 0.30 | 633 | BK7, t=0.25 |

| AL05000300 | D-ZK3 | 3.00 | 5.00 | 4.03 | 1.53 | 0.26 | 915 | N/A |

| AL06000300 | D-ZK3 | 3.00 | 6.00 | 5.20 | 1.50 | 0.21 | 635 | BK7, t=0.25 |

| AL06160470 | D-ZK3 | 4.700 | 6.16 | 4.37 | 3.48 | 0.30 | 780 | BK7, t=0.275 |

| AL06240720 | D-ZK3 | 7.20 | 6.24 | 3.43 | 5.36 | 0.40 | 780 | BK7, t=0.275 |

| AL06430630 | D-ZK2N | 6.35 | 6.43 | 4.70 | 3.11 | 0.43 | 830 | BK7, t=0.25 |

| AL08000450 | L-BAL42 | 4.50 | 8.00 | 6.73 | 2.00 | 0.22 | 915 | N/A |

| AL08000990 | D-ZK3 | 9.936 | 8.00 | 5.90 | 3.43 | 0.50 | 780 | BK7, t=0.25 |

| AL08420800 | D-ZK3 | 8.00 | 8.42 | 7.05 | 2.30 | 0.37 | 635 | BK7, t=0.25 |

| AL08800550 | L-BAL42 | 5.50 | 8.80 | 7.35 | 2.40 | 0.26 | 635 | N/A |

| AL08950650 | L-BAL42 | 6.50 | 8.95 | 7.60 | 2.36 | 0.30 | 635 | BK7, t=0.25 |

| AL10000630 | D-ZK2N | 6.35 | 10.00 | 8.29 | 3.00 | 0.28 | 635 | BK7, t=0.25 |

| AL10990720 | D-ZK3 | 7.20 | 10.99 | 7.90 | 5.032 | 0.28 | 633 | BK7, t=0.25 |

| AL11180800 | D-ZK2N | 8.00 | 11.18 | 9.69 | 2.66 | 0.31 | 635 | BK7, t=0.25 |

| AL11241500 | D-ZK3 | 15.00 | 11.24 | 6.83 | 7.00 | 0.62 | 587 | N/A |

| AL12060650 | L-BAL42 | 6.50 | 12.06 | 10.61 | 2.36 | 0.22 | 635 | BK7, t=0.25 |

| AL13850630 | D-ZK3 | 6.325 | 13.85 | 12.10 | 2.773 | 0.180 | 650 | N/A |

| AL15290650 | D-ZK3 | 6.50 | 15.29 | 13.89 | 2.209 | 0.16 | 780 | N/A |

| AL15261050 | L-BAL42 | 10.50 | 15.26 | 13.58 | 3.00 | 0.30 | 639 | BK7, t=0.30 |

| AL16701000 | L-BAL42 | 10.00 | 16.70 | 14.65 | 3.225 | 0.265 | 976 | N/A |

| AL18390650 | D-ZK3 | 6.50 | 18.39 | 17.09 | 2.18 | 0.150 | 780 | BK7, t=0.25 |

| AL19001000 | L-BAL42 | 10.00 | 19.00 | 17.00 | 3.14 | 0.23 | 915 | N/A |

| AL22580800 | D-ZK2N | 8.00 | 22.58 | 21.25 | 2.35 | 0.15 | 532 | BK7, t=0.25 |

| AL24060950 | D-ZK2 | 9.50 | 24.06 | 22.76 | 2.35 | 0.16 | 785 | BK7, t=0.25 |

| AL31990930 | L-BSL7 | 9.3 | 31.99 | 30.73 | 2.3 | 0.122 | 785 | BK7, t=0.30 |

Manufacturing and Equipment

Ultra-precision measurement aspheric molds

Precision Aspheric Mold Suite

Precision Aspheric Mold Subassembly

Precision Aspheric Mold Inner Barrel

Precision Aspheric Arrays

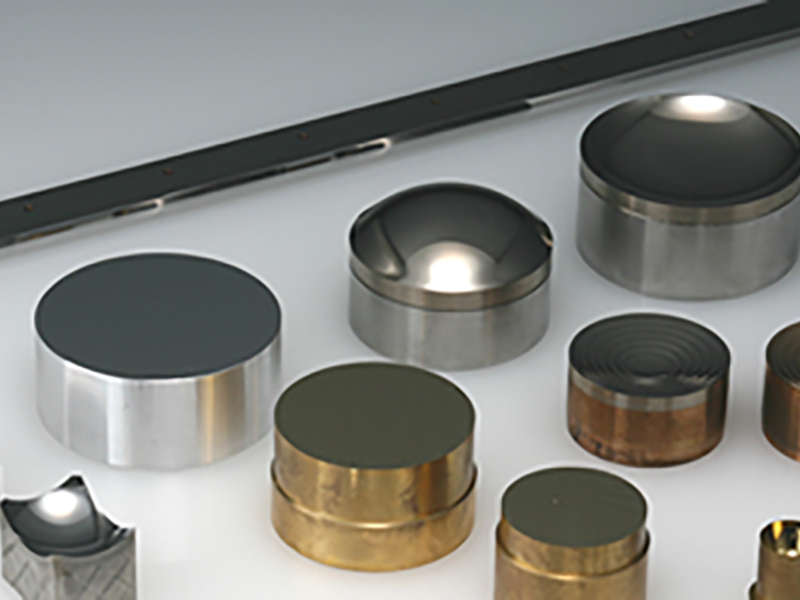

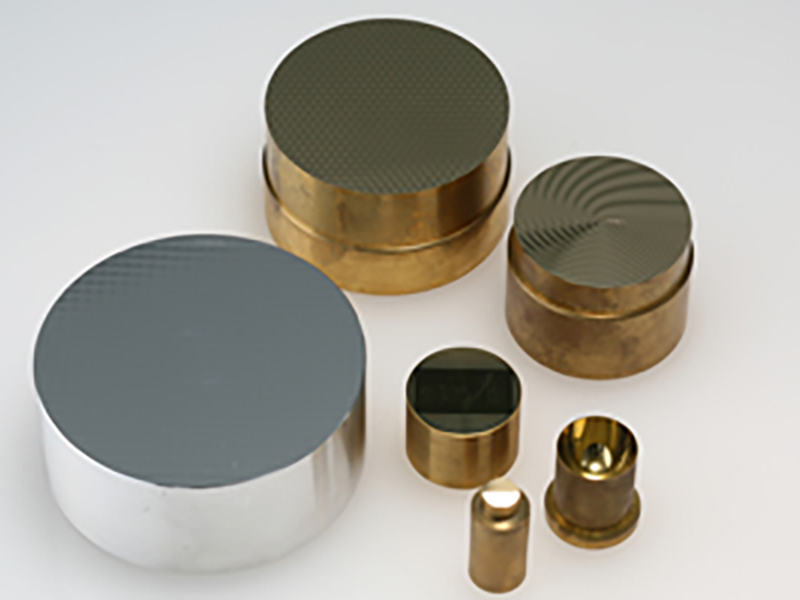

Precision Aspheric Mold Kernels

Precision Aspheric Component Measuring Instruments

Glass Aspheric Molds

Sellwell Aspheric Lens Coating

| Coating | Wavelength Range | Reflectivity |

|---|---|---|

| MLBB-A | 350 ~ 700nm | Ravg < 0.50% |

| MLBB-B | 600 ~ 1050nm | Rmax < 1.0% |

| MLBB-C | 1050 ~ 1600nm | Rmax < 1.0% |

| MLBB-Q | 1300 ~ 1700nm | Rmax < 0.25% |

| UVA | 350 ~ 600nm | Rmax < 1.0% |

| BB400-700 | 400 ~ 700nm | Ravg < 0.50% |

Customized coating are available upon negotiating, Sellwell Optics offers a variety of multilayer broadband coatings to reduce the back reflection from a nominal 6% for uncoated lenses. The choice of which AR coating is appropriate depends on the type of glass the lens is made from and the wavelength at which the lens will be used.

For more than 30 years, Sellwell Optics has been building a reputation as one of the top optical glass manufacturers in optics industry. Sellwell Optics' dedication to innovation, quality control and fast customer service has enabled us to consistently exceed the expectations of our most valued and important audience, our customers.

Optical Design

We design optical systems to meet customer’s specifications from selecting glass materials to design of lens and lens units.Precision die and preforms

We manufacture molding dies made of special alloys and ceramics which withstand high temperatures. Ultraprecision technical expertise is required to grind surfaces of metal dies to implement optical designs in a nano-order. Then, we prepare polished near-net shape preforms for

Aspheric Lens Manufacturing Procedure

Pressing

After setting preforms on a molding die, we press the preforms while heating at 300 to 700 degree Celsius until the preforms get soften. Then, anneal the pressed preforms, and aspheric shaped glasses are taken out of the molding die.

Coating

Lenses are coated upon request (e.g. anti-reflect coating).

Inspection

Lenses are inspected with the following measurement instruments.

A Part of machine & equipment Sellwell Manufacture Optics Aspheric Lenses

| Instruments | Made by | Models | Number | Measurement contents |

|---|---|---|---|---|

| 3-D Profilometer | Panasonic | UA3P-4 | 1 | Surface form of aspheric lens |

| Panasonic | UA3P-300 | 1 | Surface form of aspheric lens | |

| Panasonic | UA3P-400T | 1 | Surface form of aspheric lens | |

| Laser Interferometer | FUJIFILM | F601 | 2 | Form measurement of spherical lenses |

| FUJIFILM | FI251N | 1 | Form measurement of small spherical lenses | |

| Optical centration measurement and alignment instrument | Trioptics | OptiCentric 3D | 2 | Centration, center thickness and air gap of optical systems |

| Trioptics | OptiCentric MOT | 1 | Centration, center thickness and air gap of optical systems | |

| 3D Laser scanning microscope | Keyence | VK-X200 | 1 | Non-contact dimensional measurement |

| Measuring microscope | Mitutoyo | MF | 1 | Dimensional measurement |

| Keyence | IM-6700-6225 | 1 | Dimensional measurement | |

| Spectrophotometer | Jasco | V-700 | 1 | Transmittance |

| MTF Test station | Trioptics | Image Master HR | 1 | MTF, relative illumination, chief ray angle, distortion |

Meniscus Lens Specification

| Material | Optical glass/ Fused silica/ sapphire etc. |

| Diameter | 2mm~300mm |

| Diameter tolerance | ±0.05mm(≤50mm) |

| ±0.1mm(>50mm) | |

| Focal length | -50mm~-2000mm |

| Focal length tolerance | ±0.2%(<10mm) |

| ±0.5%(<10mm-1000mm) | |

| ±1%(<>1000mm) | |

| Center Thickness | 2mm~20mm |

| Surface quality | 60/40, 40/20, 20/10 |

| Surface accuracy | λ/2~λ/10@632.8nm,532nm |

| Clear Aperture | >85% dig diameter |

| Centration | <3arc min~ 30arc sec |

| Coating | As per customer’s request |

Meniscus Lens List

| Material | Diameter

(mm) |

Convex Surface Radius

(mm) |

Concave

Surface Radius (mm) |

Center Thickness

(mm) |

Focal Length

(mm) |

| H-K9L | 7 | 4.6 | -4.60 | 3 | 41.4 |

| H-LAF38 | 8 | 6.28 | -95.10 | 2.2 | 8.9 |

| H-ZBAF5 | 8 | 9.7 | -19.72 | 2.27 | 26 |

| H-ZF52A | 8 | 12.05 | -9.50 | 4.2 | 217 |

| ZnSe | 8.6 | 11.22 | -50.58 | 1.4 | 8.7 |

| H-ZF62 | 9 | 9.911 | -38.55 | 2.1 | 13.8 |

| H-ZF62 | 9 | 10.59 | -13.37 | 7.64 | 23.8 |

| H-K9L | 10 | 5.19 | -500.00 | 6.2 | 10.1 |

| JGS1 | 10.802 | 7.69 | -7.28 | 3 | 226.1 |

| H-K9L | 11 | 16.57 | -156.37 | 3 | 35.5 |

| H-LAF50A | 12 | 13.176 | -132.74 | 3.3 | 18.7 |

| H-ZK9 | 12 | 11.57 | -48.93 | 2.86 | 23.7 |

| H-ZBAF21 | 12 | 15.374 | -65.11 | 3 | 27 |

| H-ZK3 | 13 | 8.088 | -21.23 | 4 | 23.2 |

| S-LAM7 | 13 | 16.94393 | -170.00 | 2.5 | 24.9 |

| H-ZLAF75A | 14 | 13.804 | -51.24 | 2.4 | 20.1 |

| H-ZF7LA | 14 | 11.324 | -5.50 | 9.54 | 49.3 |

| H-K9L | 14 | 10.36 | -14.62 | 5 | 50.3 |

| H-ZLAF68 | 14 | 10.16 | -6.87 | 6.4 | 282.2 |

| H-ZF6 | 15 | 119 | -18.95 | 3.86 | 30.3 |

| H-LAF3B | 15 | 20.73 | -145.88 | 2.8 | 32.2 |

| H-K9L | 15 | 9.26 | -18.16 | 3.5 | 32.3 |

| H-ZLAF55A | 15 | 28.847 | -293.95 | 3 | 38.1 |

| H-ZK3 | 15.2 | 15.3 | -231.90 | 2.8 | 27.67 |

| LAF10 | 15.5 | 24.66 | -163.59 | 2.7 | 36.52 |

| H-LAF53 | 16 | 12.823 | -33.57 | 4.8 | 25.4 |

| H-ZLAF52 | 16 | 18.67 | -67.51 | 3 | 31.2 |

| H-ZK6 | 16 | 13.996 | -34.67 | 3.5 | 36.4 |

| H-LAK4 | 16 | 22.7 | -39.63 | 4 | 74.8 |

| H-ZLAF68 | 16 | 11.251 | -7.74 | 4.8 | 78.1 |

| ZK9 | 17 | 11.695 | -11.70 | 7 | 81.4 |

| H-ZF13 | 18 | 96.302 | -26.99 | 1.5 | 48.2 |

| H-K9L | 18 | 36.4 | -51.52 | 3.5 | 222.45 |

| H-LAF10L | 18.98 | 21.38 | -32.36 | 3.6 | 69.8 |

| H-ZK9A | 19 | 13.895 | -29.05 | 3.6 | 39.4 |

| ZK7 | 19.4 | 17.783 | -43.05 | 3 | 47.29 |

| H-LAF53 | 20 | 16.482 | -55.46 | 4 | 30.1 |

| H-ZK10 | 20 | 18.054 | -35.41 | 5 | 53.3 |

| H-ZLAF66 | 20 | 21.099 | -28.09 | 5 | 80.3 |

| H-ZK7 | 20 | 60.67 | -778.00 | 2.9 | 106.8 |

| H-BAK4 | 22 | 17.497 | -114.52 | 4.7 | 36.7 |

| H-LAK3 | 22 | 21.04 | -39.81 | 3.8 | 54.7 |

| H-ZBAF3 | 22 | 38.9 | -498.90 | 2.7 | 63.8 |

| H-K9L | 22 | 72.44 | -1130.00 | 5 | 149.5 |

| H-BAK4 | 22.5 | 24.619 | -1735.00 | 5 | 45 |

| H-ZF7LA | 22.6 | 22.44 | -28.91 | 9.88 | 74 |

| H-LAF53 | 23 | 16.788 | -36.22 | 5 | 38 |

| H-LAF53 | 23 | 16.788 | -36.22 | 5 | 38 |

| BAF5 | 23 | 32.8 | -219.10 | 3 | 62.3 |

| H-ZK1 | 23.4 | 46.48 | -176.06 | 4.56 | 109.6 |

| H-LAK59 | 23.48 | 102.33 | -194.98 | 2.5 | 308.2 |

| H-ZF7LA | 24 | 17.819 | -30.30 | 10 | 39.6 |

| H-K9L | 25 | 17.3 | -27.00 | 4.55 | 80.3 |

| H-K9L | 25.4 | 32.1 | -82.20 | 3.6 | 100 |

| JGS1 | 25.4 | 31 | -91.20 | 4 | 100 |

| H-K9L | 25.4 | 66.2 | -182.20 | 2.8 | 200 |

| JGS1 | 25.4 | 64.2 | -209.80 | 2.9 | 200 |

| H-K9L | 25.4 | 100.9 | -288.20 | 2.5 | 300 |

| ZK9 | 25.5 | 22.96 | -89.26 | 4.4 | 48.59 |

| N-SF6 | 26 | 32.15 | -176.40 | 4 | 43.2 |

| H-LAK3 | 26 | 26.79 | -127.94 | 4.2 | 44.4 |

| H-K9L | 26 | 23.93 | -331.70 | 6 | 49.58 |

| H-ZK11 | 27 | 23.07 | -77.04 | 4.8 | 49.8 |

| H-LAK1 | 27 | 26.24 | -74.99 | 4.1 | 59.8 |

| H-ZK10 | 27 | 38.688 | -1541.90 | 5 | 63.7 |

| H-ZK10 | 27 | 43.279 | -311.79 | 5 | 80 |

| H-ZK9 | 28 | 21.82 | -83.35 | 5.5 | 46.07 |

| H-ZBAF21 | 28 | 37.865 | -862.87 | 3.5 | 54.7 |

| H-LAF53 | 30 | 18.75 | -52.24 | 7.5 | 35.9 |

| H-K9L | 30 | 18.8 | -37.95 | 5.9 | 65.7 |

| ZK9 | 32 | 23.99 | -42.85 | 8 | 75.58 |

| H-BAK4 | 33 | 23.4 | -38.20 | 6.2 | 95.14 |

| H-K9L | 33 | 50.35 | -85.11 | 3.1 | 231.74 |

| H-ZF6 | 33.5 | 213.8 | -46.03 | 2.97 | 71.9 |

| H-ZK98 | 34 | 49 | -75.00 | 4.5 | 213.7 |

| H-ZBAF3 | 35 | 38.15 | -212.35 | 10 | 69.2 |

| H-K9L | 36 | 64.9 | -116.41 | 3.6 | 277.48 |

| H-ZBAF3 | 40 | 52.2 | -2148.00 | 12.1 | 81.3 |

| H-K9L | 40 | 45.71 | -62.37 | 3.5 | 309.27 |

| H-K9L | 41 | 78.52 | -622.30 | 4.1 | 173.57 |

| H-K9L | 41 | 65.77 | -111.94 | 3.7 | 300.61 |

| F2 | 42 | 28.5 | -71.30 | 8.8 | 71.8 |

| H-ZBAF20 | 42 | 32.137 | -59.02 | 14 | 82.8 |

| H-QK3L | 42 | 35.471 | -34.95 | 14.1 | 621 |

| H-ZF6 | 43.2 | 51.2 | -71.28 | 4 | 221.7 |

| H-QK3L | 44 | 37.026 | -239.30 | 8 | 88.7 |

| H-ZF6 | 45 | 48.91 | -87.90 | 5 | 136.7 |

| H-K9L | 48.5 | 72.44 | -150.31 | 4.5 | 265.57 |

| H-ZK11 | 49 | 32.81 | -104.23 | 11.4 | 70.6 |

| H-K9L | 50.5 | 81.75 | -145.88 | 4 | 352.64 |

| H-K9L | 58 | 107.15 | -477.00 | 7 | 265.1 |

| F4 | 59 | 1267.1 | -266.16 | 5 | 544 |

| H-K9L | 60 | 39.72 | -142.41 | 13.8 | 102 |

| H-K9L | 60.274 | 66.37 | -178.49 | 10.66 | 198 |

| H-K9L | 60.274 | 122.987 | -424.51 | 10.66 | 331 |

| H-ZF2 | 74 | 65.851 | -121.34 | 9 | 201 |

| H-ZBAF21 | 76 | 157.04 | -306.97 | 6 | 437 |

| H-K9L | 81 | 203.7 | -2773.00 | 9.96 | 424.84 |

| H-LAK7 | 104 | 181.59 | -320.37 | 12 | 567.4 |

| H-K9L | 106 | 110.1 | -257.80 | 11.3 | 362.4 |

Sellwell Optics's high precision glass molding technologies is able to enable mass volume production of aspheric lenses with maintaining the ultra-precised quality at an resonable price comparing to others. Because glass molding is the most consistent and economical manufacturing method to produce aspherical lens in large volume, Sellwell Optics has completely perfected this method to offer the most precise aspheric lens available. Sellwell Optics offers standard and custom-made aspheric lenses, all designed by our professional optical design engineers.

Sellwell Optics aspheric lens manufacturing supports a wide range of optical glass, lens designers are freedom to select the glass that is best suited to the their applications.

Using Sellwell Optics's aspheric lens benefit from the quality and performance of all-glass aspherical lenses

- Easily transition from prototype phase to high-volume production.

- Customize to fit your application or choose from over 100 standard aspheric designs.

- RoHS-compliant, ultra-high quality glass.

Please contact us via sales (at) sellwellgroup.com, sales (at) aspherics.com